High-Volume Components

Sweating the details of design for manufacture.

Our product engineering teams thrive on surpassing program objectives for weight, cost, functional performance and efficiency of manufacture.

Product development is a collaborative effort between engineering and manufacturing.

Design for Manufacture (DFM) at work…

An “Industry First” when developed in the early 2000’s, the Multimatic StepGate™ has evolved to streamline production with reduced complexity.

The first-generation StepGate™ incorporated 140 parts in six subassemblies and required multiple assembly operations including laser and MIG welding.

… in pursuit of manufacturing efficiency.

By sweating the details, the second-generation Multimatic StepGate™ is manufactured using high-speed, press-based assembly techniques, eliminating welding, and allowing installation with just six bolts.

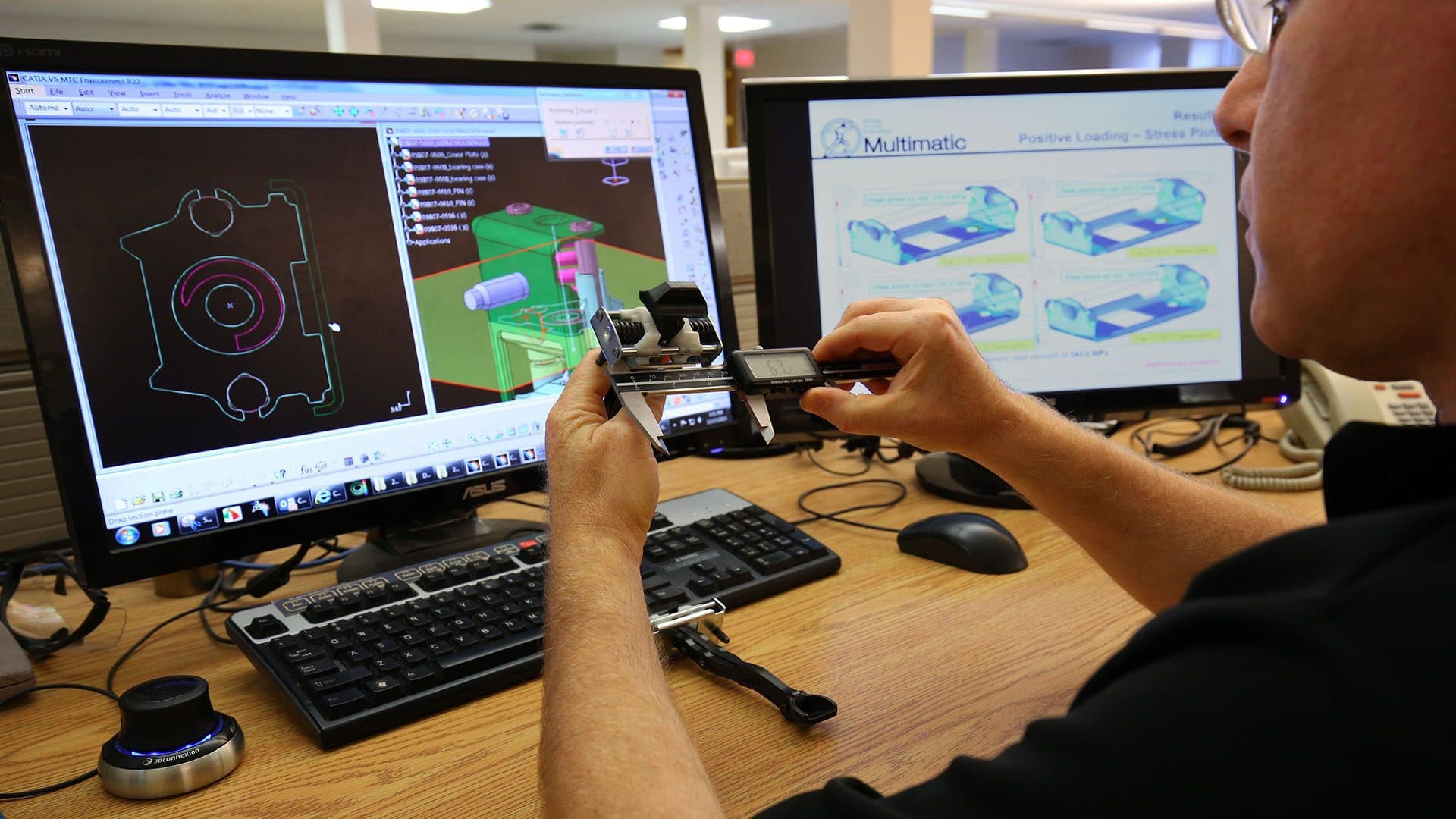

Our global engineering facilities leverage:

- State-of-the-art design tools

- In-house prototyping and testing resources

- Advanced Product Quality Planning (APQP) disciplines:

- DVP&Rs

- DFMEAs

- Open issues reporting and resolution

- Fully integrated timelines with resource planning

- Feedback and support from our manufacturing plants